1. Safety Fuse

Uses - To initiate non-electrical detonators

Ingredients: Black Powder

Properties:

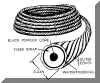

Safety fuse is a length of strong, flexible, rope-like product with a black powder core. It is designed to be initiated with a specialty designed fuse lighter or match, burn its length at a predetermined rate, and initiate a non-electric detonator. Safety fuse normally burns at a rate of approximately 35- 45 sec/ft.

Construction:

Safety fuse is constructed with various types/quantities of natural and man made fibers and plastic. Safety fuse can usually be identified by its color, wax finish and other manufacturing characteristics observed on its exterior. However, with the use of colored plastics as a final covering, it may be misidentified.

2. Detonators

Initiator is a term that is used in the explosive industry to describe any devise that may be used to start a detonation or deflagration.

Devices that are used to initiate high explosives are called detonators and devises that start burning or deflagration are called squibs or igniters.

Detonators are used for initiating high explosives and contain small amounts of a sensitive primary explosive. Although they are manufactured to absorb a reasonable amount of shock during handling and transportation, they should not be abused.

In general detonators consist of an ignition charge, intermediate charge, and a base charge. Each charge in the train is selected and used to transition from heat to shock.

a. Non Electrical Detonators

(1.) Uses - To initiate other explosives, detonating cord and shock tube.

(2.) Ingredients:

May include the following:

Lead Azide

Lead Styphnate

PETN

RDX

(3.) Properties:

Non-electrical detonators or fuse caps are thin metal or paper cylindrical shells, open on one end for the insertion of safety fuse, which contain various types of primary and secondary explosives. They are sensitive to heat, shock and crushing and are designed to be initiated with safety fuse or detonating cord. They are normally rated as #8 strength. All detonators of this type are instantaneous and therefore, do not have a delay elements.

(4.) Construction Characteristics:

(a.) Shell material

Aluminum

Copper

Guilding metal

Paper

(5.) Explosives: Contain approximately .65 grams of high explosives.

(6.) Markings:

Each shell is marked with a high explosive statement which identifies it as a high explosive and dangerous. Additionally, some of the manufacturers may place their company logo on the shell. The color of the printing is determined by each manufacturer.

(7.) Length: Approximately 2 3/8 inches

(8.) Diameter: .292 inches

b. Electrical Detonators

(1.) Uses - To initiate other explosives, detonating cord and shock tube.

(2.) Ingredients:

May contain one or more of the following:

RDX PETN

Tetryl Lead Azide

Lead Styphnate DDNP/Diazo (Diazodinitrophenol)

Additional proprietary mixes may be utilized for the ignition charge, match and delay elements.

(3.) Properties:

Electrical detonators are similar to non-electrical detonators except they are initiated by the application of electrical current through electrical wires. The current causes a bridge wire or match elements to heat/function thereby, causing the ignition charge to explode which in turn, causes a chain reaction to cause the base charge to be initiated. The wires are secured into the detonator by a closure plug, crimped into the shell, which seals the explosive from moisture. In addition to sensitivity from heat, shock and crushing, these products are subject to extraneous electricity due to the presence of electrical wire.

(4.) Types:

(a.) Instantaneous

(b.) Short period delay

(c.) Long period delay

(d.) Seismic

(e.) Electronic delay

c. Shock Tubes

(1.) Uses - To initiate boosters, detonating cord, other lengths of shock tubes and other explosives. This type of initiation is common to the construction industry, the fire officer will generally find this type of system stored in construction related magazines.

(2.) Ingredients:

HMX and Aluminum Powder

(3.) Properties:

Shock tube is a small diameter plastic laminate tube coated with a very thin layer of reactive material at one (1) pound per 100,000 feet of tube. When initiated, shock tube transmits a low energy signal or propagation wave, at approximately 6,500 ft/sec from one point to another. This shock wave is similar to a dust explosion and will propagate through most sharp bends, knots and kinks in the tube. The detonation is sustained by such a small quantity of reactive material, the outer surface of the tube remains intact during and after functioning. Shock tube can be initiated by small shotshell-type primers, detonating cord or detonators.

(4.) Types:

Instantaneous

Short period delay

Long period delay

Alternative Types

Connectors

In-line delays

Bunch blocks

Lead in line

(5.) Construction Characteristics

(a.) Shell

Aluminum

Diameter: .29

Length: 2 3/8 to 4 inches

(b.) Tube materials

Construction

Polyethylene

Surylyn

Explosives

HMX

Aluminum powder

Length: 3 to 2500 feet

Diameter: .12 inches

3. Squibs and Igniters

a. Squibs

Squibs are used for the electrical initiation of low explosives.

b. Igniters

Ignitors are used for the initiation of safety fuse. There are two types, the military version and the commercial version.

Military

Commercial